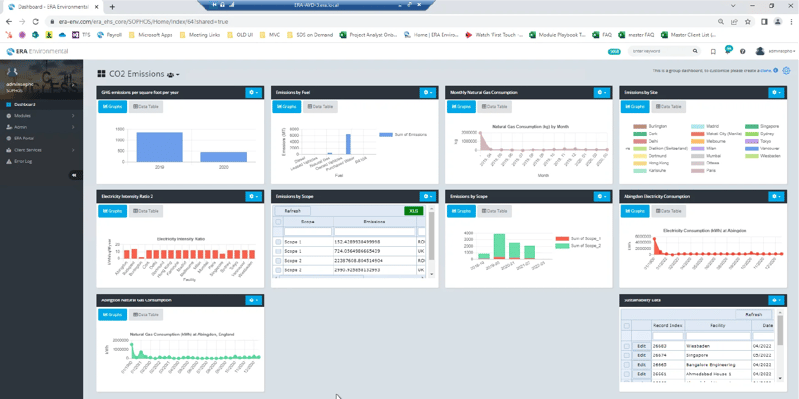

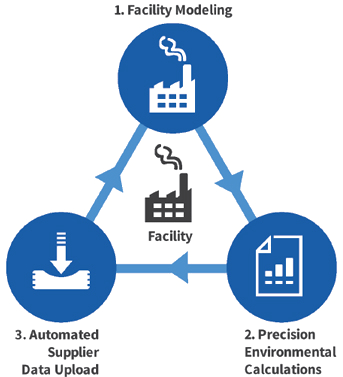

With a virtual map of your facility, inventory, and sources, you are guaranteed maximum accuracy when modeling your emissions and generating EHS reports. Prepare for emissions testing of greenhouses gases, and reduce your carbon and ecological footprint. Comply with the EPA National Emissions Inventory.

Understand your facilities' sources and outputs by turning them into executive KPIs and any one of 400+ environmental reports

Explore every relevant avenue of potential source-related compliance issues and avoid fines down the line related to green house gasses with ERA's integrative modeling platform.

Measure and compare the performance of facilities across your entire organization with our environmental pollutant modelling software. GHG emissions modelling made easy.

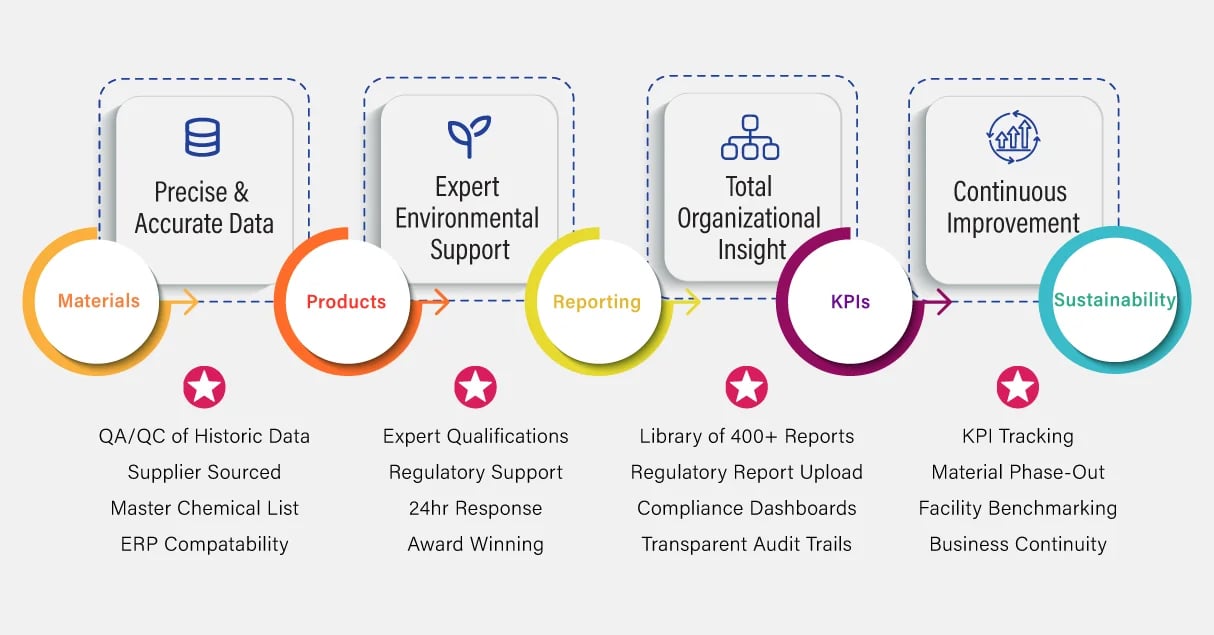

We model your materials exhaustively and engage all input sources, including those from your suppliers.

Our comprehensive approach to data accuracy paints the most complete picture of your business operations.

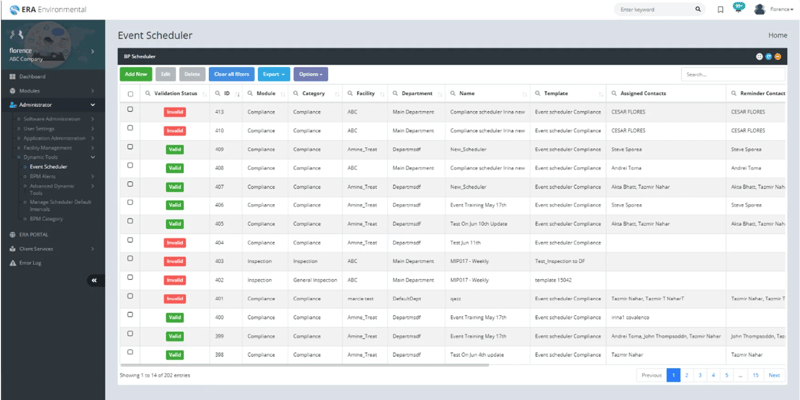

Once your data has been checked for errors and validated, our system transforms it into a wide array of reports, assessments, and analyses that can, in turn, optimize your operations and your relationship with your suppliers.

Streamlining your environmental compliance workflows starts with cutting back on redundant work and keeping accurate records. Read our 13-page eBook highlighting the benefits of material data management automation for both EHS managers and vendors.

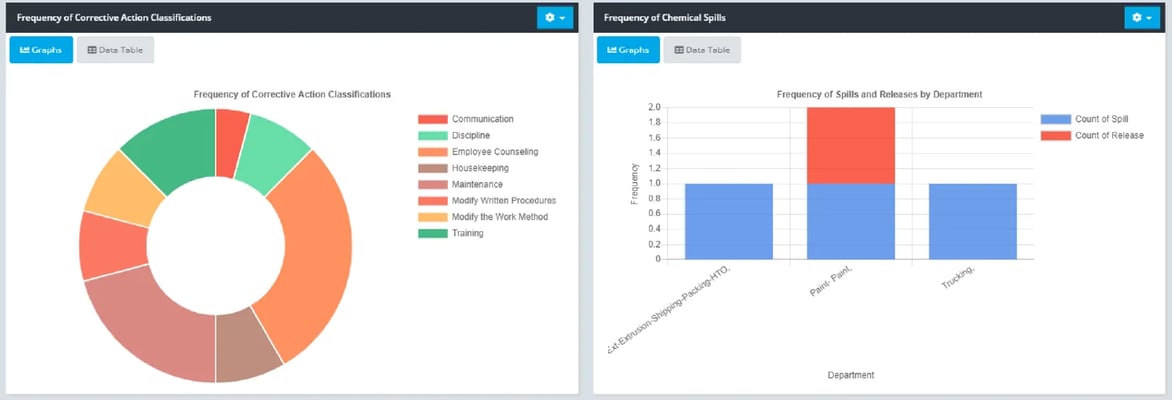

Control how regulatory tracking is done by differentiating how chemicals are used and stored on-site

Create chemical groups and/or limits according to your permits' compliance requirements