With ERA, OEMs and automotive suppliers can maintain regulatory compliance, reach industry sustainability goals, and become better partners at any stage in the supply chain while reducing EHS overhead by up to 80%.

.png?width=550&height=350&name=Tier-II-solution-webpage_desktop%20(1).png)

Demonstrate your ESG efforts, track scope 1, 2, and 3 emissions, and meet key sustainability standards

Track air, water, and waste emissions and releases accurately and automate report generation

Streamline incident workflows, manage inspections and audits, and facilitate risk management

.png?width=181&height=125&name=McNeilus_ERAautomotiveclient(Trucks).png)

.png?width=181&height=125&name=ARE_ERAautomotiveclient%20(Trucks).png)

.png?width=181&height=125&name=jerrdan_ERAautomotiveclient%20(Trucks).png)

.png?width=181&height=125&name=IMT_ERAautomotiveclient(Trucks).png)

.png?width=181&height=125&name=LEER_ERAautomotiveclient(Trucks).png)

.png?width=181&height=125&name=continental-motors_ERAautomotiveclient(Trucks).png)

.png?width=181&height=125&name=Pierce_ERAautomotiveclient(Trucks).png)

.png?width=181&height=125&name=morgan_ERAautomotiveclient(Trucks).png)

.png?width=181&height=125&name=Reading%20truck_ERAautomotiveclient(Trucks).png)

.png?width=125&height=125&name=BlueBird_ERAautomotiveclient(Trucks).png)

.png?width=181&height=125&name=OshKosh_ERAautomotiveclient(Trucks).png)

.png?width=181&height=125&name=UnicellLogo_ERAautomotiveclient(Trucks).png)

All your EHS data is maintained in one platform, facilitating collaboration and avoiding redundant work.

Handle every detail of your environmental reporting, with industry-specific standards for VOC protocol, MACT, and more.

Tailor dashboards to specific roles and individuals with built-in and custom KPIs, data visualization, and insights.

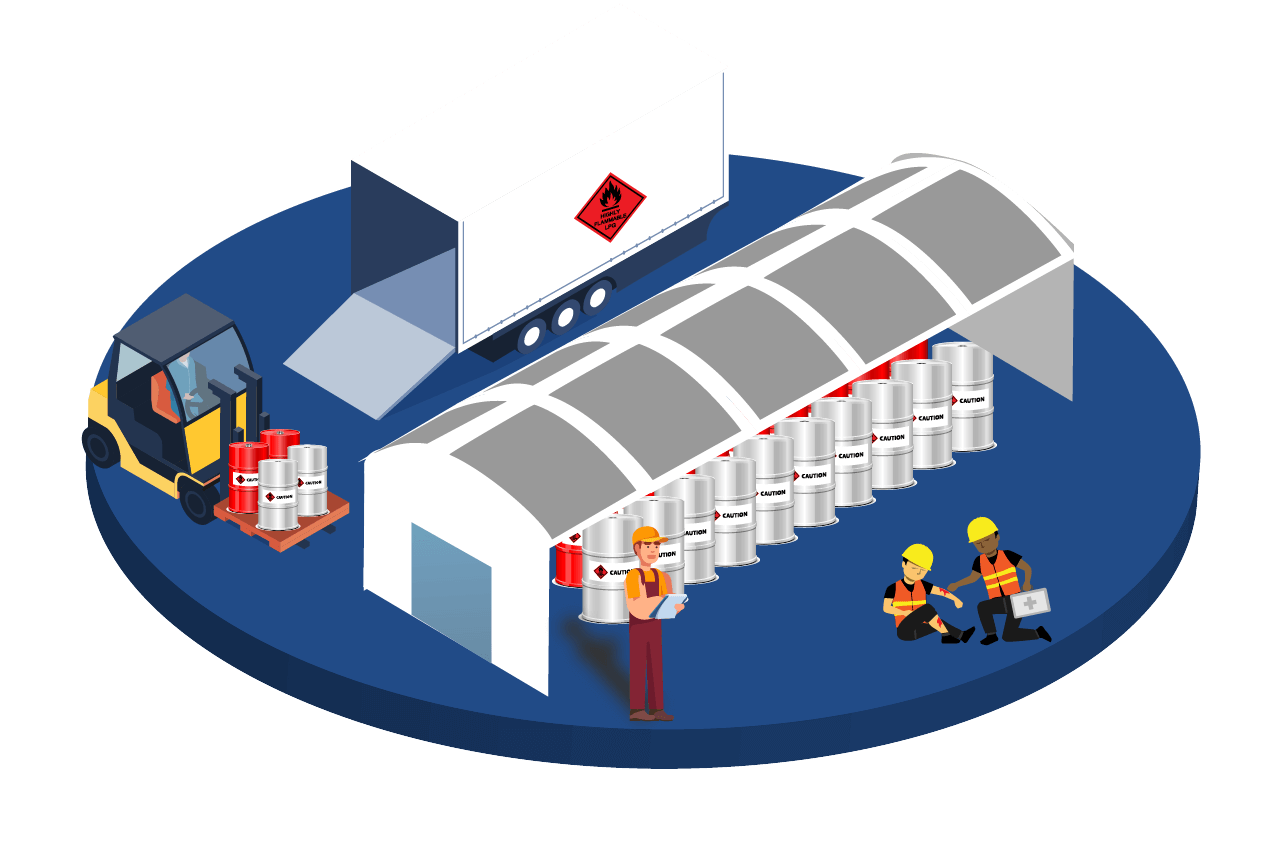

ERA’s Environmental Management System helps OEMs and auto suppliers maintain environmental compliance with federal and state requirements throughout North America and demonstrate that they meet continuously shifting industry standards.

Automate tracking of emissions and waste throughout your operations based on actual data from your facility and thorough process mapping and calculations. Monitor categories including, HAPs, VOCs, GHGs, and more, along with speciated chemicals.

Access chemical data from a wide range of coating suppliers through ERA's chemical vendor partnership program, including PPG, AkzoNobel, Sherwin-Williams, and many more. ERA’s Master Chemical and Regulatory List is kept up to date by our scientists to ensure that you have complete data on more than 200,000 chemicals.

Over 500 built-in air, water, and waste reports automate and streamline your environmental reporting. Ensure accuracy for your TRI, Tier II, Title V, NPRI, DMR, NESHAP, MACT, and other key reports, and take advantage of direct uploads where supported.

Track production numbers and material use together to generate clear and accurate insight into amounts used per unit and by surface area. Have ready access to the paint and coatings records automotive manufacturers need to maintain compliance.

ERA’s Sustainability Software makes it possible for OEMs and auto suppliers to standardize their commitment to sustainability across facilities and show partners throughout the industry the impact of their ESG efforts.

Share your sustainability efforts with the public through water security and climate change reports for direct upload to CDP. Highlight sustainability performance for stakeholders with EcoVadis reports.

Face increasing industry pressure to achieve complete lifecycle carbon accounting with detailed calculations for scope 1, 2, and 3 emissions throughout your facility and supply chain.

Automate report generation to achieve and maintain certification with organizations including, GRI, CDP, SASB, DJSI, and more. Custom corporate responsibility reports let you highlight your organization’s efforts.

Track not just emissions and waste but a wide range of ESG metrics covering environmental, social, and governance. Improve your organization’s public image and move your sustainability strategy beyond short-term returns.

ERA’s Health & Safety Software lets OEMs and auto suppliers take a proactive approach to health & safety in terms of planning, response, and tracking. Meet industry standards with robust inspections and audits tailored to your operations.

Standardize incident reporting across facilities within your organization and ensure that all H&S data is accessible and complete. Automate CAPA responses and compliance task management.

Custom inspections enable your organization to take a proactive approach to safety that address your unique internal safety requirements. Built-in safety audits keep your operations compliant with relevant automotive industry safety regulations.

Assess qualitative and quantitative risk metrics and immediately update risks based on new information from audits and inspections. Plan and automate risk mitigation and follow-up tasks, including delegations, tracking, and reporting.

Streamline your employee training with custom courses and detailed training calendars. Automated notifications and tracking keep your team up-to-date during onboarding, refresher courses, and new developments.

Thorough and accurate tracking, monitoring, and reporting for chemical use, emissions, releases, and waste throughout your operations.

We work with you to accurately map the flow of all materials throughout your processes, no matter how complex.

Model every automotive manufacturing step with sub-modules that accurately reflect your actual operations.

Thorough mass balance calculations and equipment factors provide accurate values for use, emissions, and waste.

Discover how Title V air permit requirements impact the automotive industry and whether you need one.

Understand your requirements for automotive industry MACT and NESHAP compliance.