ERA's storage tanks emissions software gives you a simple and reliable way to produce extremely accurate emission reports for all the tanks in your facility.

.png?width=550&height=350&name=Tier-II-solution-webpage_desktop%20(1).png)

.webp?width=550&height=350&name=Hero_tanks%20(1).webp)

We cover scenarios for any type of tank and tank roof, including heating, breathing, loading (mobile sources), blending, and more

Built-in regulatory formulas for over 200,000 chemicals are always kept up to date within our Master Chemical List

Save countless hours of data management and minimize manual entry errors with automated report generation

Our stress-free tanks management platform calculates VOC emissions and PM releases resulting from the normal and special operation of every type of tank/vessel and the loading of mobile sources.

The system is modeled after EPA Tanks 4.0 but includes published updates to AP-42 Section 7.1 and additional calculations listed by the American Petroleum Institute

Emission reports pull from Antoine and Riedel coefficients, meteorological data from the nearest city, and HAPs, VHAPs, and VOC content values from parsed SDS

VOC-speciated, total VOC, replica EPA Tanks 4.0, working losses, breathing losses, material compositions with/without full speciation... our reporting engine does it all!

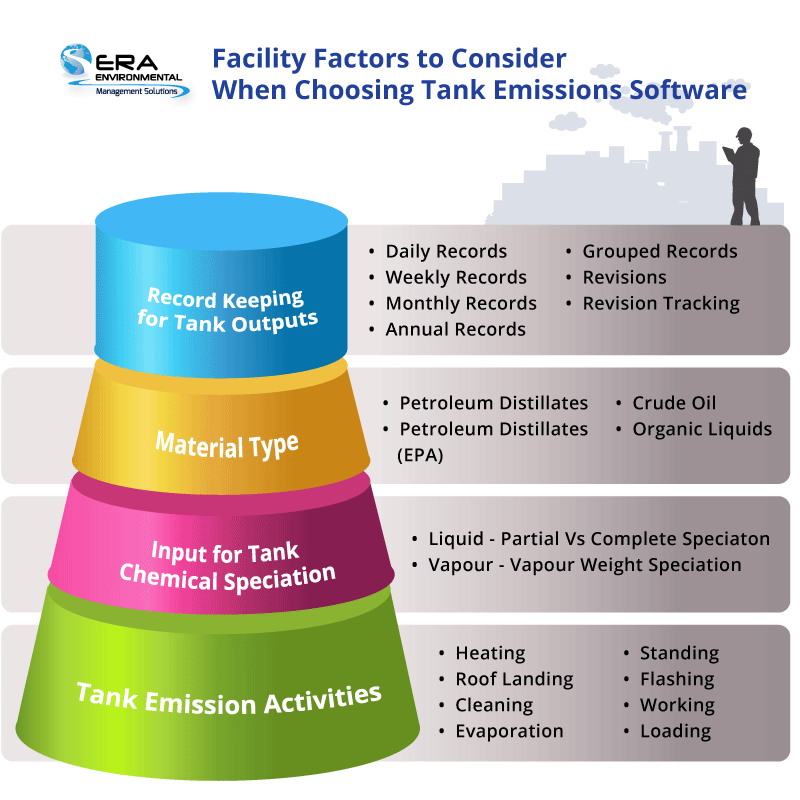

Tank emissions, with a vast array of physical and mathematical factors, can be challenging to calculate. Our dedicated tank solution accounts for every variable to ensure you produce exactly the reports you need, tailor-made for you.

Custom, facility-dependent features include:

Material Modeling of the chemical properties of the products stored, mixed, heated, etc.

Reid Vapor Pressure (RVP) values for crude oil and refined petroleum liquids

Dynamic monthly temperature records

Enhanced True Vapor Pressure (TVP) determination (based on temperature records)

Subpart OOOO and Ground Level Concentration (GLC) reporting

ERA assigns a dedicated EMS professional to guide you through the setting up and the day-to-day operation of your Tanks Emission Software, guaranteeing it is calibrated to your facility's exact specifications.