With the addition of the EPA Toxic Release Inventory (TRI) report to your compliance checklist, it is normal to be confused about where to begin. ERA has assisted hundreds of facilities with their annual TRI reporting and would like to share some knowledge to get you started on data collection and meeting reporting requirements.

As mentioned in ERA’s TRI regulation announcement blog, it is critical to become acquainted with TRI regulations and reporting standards. This means thoroughly studying the reporting criteria, definitions of manufacture, process and otherwise use, types of chemicals and thresholds, chemical releases, transfers, waste management and pollution prevention information.

What Data is Required for TRI Reporting?

Records Required For NGP TRI Reporting

It would be best if you had comprehensive recordkeeping for your natural gas processing operations, meaning you should prioritize the collection of the following (TRI Guideme EPA., n.d):

- Safety Data Sheets (SDS).

- Process flow diagrams.

- Air emissions reports.

- Production and chemical purchasing records from suppliers.

- Monitoring records for air, waste, and water discharges.

- Sampling/analytical data on waste and water discharges, with reports

- Waste profiles, manifests, and reports.

Can You Leverage Your Current Environmental Reports?

To lighten the load of the preparation of your first TRI, evaluate all the records listed above to check if you don’t already keep them for any other environmental compliance reports. This data can be advantageous when formulating your TRI report.

Natural gas processing facilities are subject to air toxics regulations, greenhouse gas (GHG) reporting to the EPA’s GHGRP, Energy Information Administration reporting, and many others.

The air regulations for equipment and processes in NGPs fall under the New Source Performance Standards (NSPS) for volatile organic compounds (VOCs) and the National Emissions Standards for Hazardous Air Pollutants (NESHAPS). The regulations address compressors, controllers, and sweetening units. Below are two examples of rules that require emissions monitoring and data collection(EPA Air Rules for Oil and Gas Industry., n.d).

|

NSPS Requirements for New and Modified Compressors Compressors that have wet seals (i.e., use oil to seal barriers to minimize fugitive emissions) should reduce their VOC emissions by flaring or redirecting the captured gas to a compressor suction or fuel system. Monitoring this requires accounting for air and waste discharge data, emission source, and reduction in your TRI recordkeeping. |

|

Air Toxics Requirements for Glycol Dehydrators The EPA requires large dehydrators to emit less than 1 ton of benzene per year. Based on the unit’s natural gas throughput and composition, small glycol dehydrators must meet a unit-specific limit of benzene, toluene, ethylbenzene, and xylene. This means you must know the chemical composition of the liquid in your dehydrators and keep updated SDS to determine VOC content and other emission information. |

Natural gas processing facilities must also report to the Energy Information Administration. The EIA program requires the submission of form 64A and form 816. The EIA form 64A collects information on natural gas inputs entering processing plants and natural gas liquids produced. EIA form 816 collects material balance information on products from natural gas processing plants, including inputs, receipts, production, and natural gas products used as fuel. If your facility reports to this program, that means you already have the manufacturing and chemical purchasing records applicable to your report (NEPIS EPA., 2009).

Monitoring the above-mentioned factors requires knowledge of chemical composition and process emissions. Only you know the type of equipment at your natural gas processing facility and its waste and emission potential. Since you already track these variables using various devices, leverage this information to highlight how you redirect and dispose of gases in your facility.

Completing a full audit of this information and applying it to this new report will be helpful in deciding which records you will need to collect from scratch.

Evaluate your Processes for Threshold Determination and Limits

After verifying the records you already have, classify how your facility manufactures, processes, or otherwise uses TRI chemicals (activity determination), whether these chemicals have any qualifiers for reporting, and if they exceed the reporting threshold.

To establish your TRI reporting threshold, you must quantify the total amount of TRI-listed chemicals or chemical categories manufactured, processed, or used in your natural gas refining process over the reporting year. You can then compare the amounts to the thresholds. Most natural gas liquids have TRI-listed chemicals, so you must have SDS on hand and an accurate process evaluation strategy.

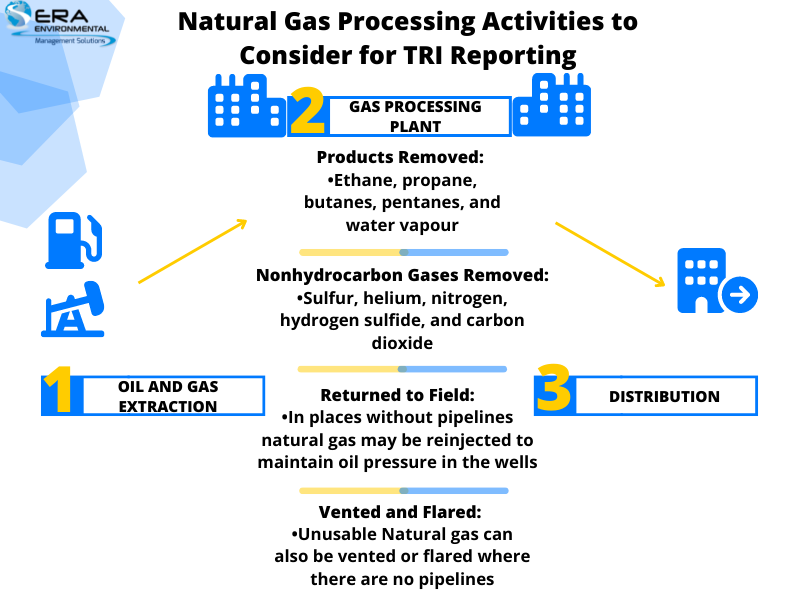

Manufacturing refers to deliberately producing an EPCRA Section 313 chemical or unintentionally creating it as a byproduct. The latter is more relevant to natural gas processing activities because the extracted hydrocarbons are byproducts of the process as shown in the image above. Manufacturing can also take place during waste treatment or as a result of fuel combustion.

When taking into account processing activities, one should pay special attention to products used for absorption, such as amine solutions used for hydrogen sulfide removal, or the diethylene glycol (DEG) and tri-ethylene glycol (TEG) which is essential in the glycol dehydration process for water absorption (U.S Energy Information Administration., 2016). Even though the main product being processed is natural gas, which is mainly composed of methane, these chemicals are also treated after they absorb the intended impurities in natural gas.

‘Otherwise use’ activities may include disposal, stabilization, and treatment of a TRI-listed chemical. The chemicals mentioned above can also fall under the ‘otherwise use’ category if they are used for absorption. This also includes chemical processing and manufacturing aids such as solvents or refrigerants.

Overall, the TRI thresholds for these processes are:

- 25,000 pounds/year for manufacturing activities

- 25,000 pounds/year for processing activities

- 10,000 pounds/year for otherwise use activities

These are the thresholds for TRI chemicals unless otherwise stated. For example, threshold limits for persistent bio-accumulative toxic chemicals (PBT) are lower because they are more harmful.

Some chemicals, such as sulfuric acid, have reporting qualifiers that make them subject to reporting only if they are in an aerosol form. If you are unsure about your chemicals’ status, refer to the EPA’s TRI reporting guidance information.

Using TRI reporting software like ERA’s environmental reporting module can simplify the threshold determination process by automatically flagging the chemicals for reporting, even those with qualifiers.

Submitting your Natural Gas Processing TRI Report

After classifying the use of chemicals under process, manufacture, or otherwise use categories, you must calculate your EPCRA 313 chemical throughput to see if they exceed the defined thresholds.

Seeing as this is your first report, you must also register for your Central Data Exchange (CDX) account and use the TRI-Me web application to prepare your forms. Certify your documents and submit them by July 1st of each year. After this, make sure you keep up with TRI updates for each subsequent report and improve your data collection using the knowledge you acquired in previous years.

Consider Reporting Assistance with TRI Reporting Software

ERA’s TRI reporting software is a robust platform that incorporates all the required reporting facilities, parent company, and treatment facility information. It accurately makes threshold determinations for the amount manufactured, processed, and otherwise used from built-in product setup options thanks to ERA’s Master Chemical and Regulatory List. It also allows you to preview your report results while troubleshooting for inconsistent or abnormal values. Finally, it helps you upload all the data into EPA’s TRI-MEweb reporting software and provides TRI report documents for your reference, making the reporting process smooth and straightforward.

If you would like ERA’s assistance with your TRI report, book a discovery call with a project analyst below.

References

- Environmental Protection Agency. (n.d.). Toxics Release Inventory (TRI) Guideme. EPA. Retrieved April 1, 2022, from https://ordspub.epa.gov/ords/guideme_ext/f?p=guideme%3Agd%3A%3A%3A%3A%3Agd%3Apetro_2_11

- SUMMARY OF REQUREMENTS FOR PROCESSES AND EQUIPMENT AT NATURAL GAS PROCESSING PLANTS. (n.d.). Retrieved April 1, 2022, from https://www.epa.gov/sites/default/files/2016-09/documents/20120417summaryprocessing_equipment.pdf

- THE NATURAL GAS DISTRIBUTION AND NATURAL GAS PROCESSING SECTORS PROPOSED RULE FOR MANDATORY REPORTING OF GREENHOUSE GASES. (2009). https://nepis.epa.gov/Exe/ZyPDF.cgi/P1009F1L.PDF?Dockey=P1009F1L.PDF

- S. Energy Information Administration. (2016). Natural Gas Explained - U.S. Energy Information Administration (EIA). Eia.gov. https://www.eia.gov/energyexplained/natural-gas/

This Blog was Co-Authored By:

April 12, 2022

.png?width=800&name=NGP-TRI-Blog-Infographic%20(1).png)

Comments