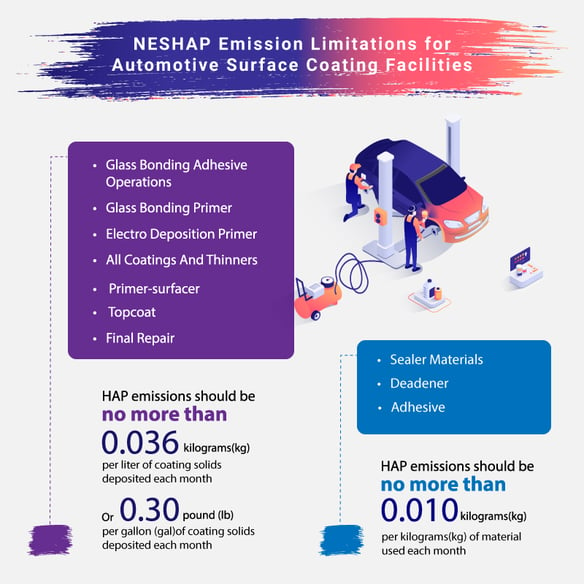

Monitoring and reducing the Hazardous Air Pollutants (HAPs) emitted during manufacturing activities, should be a priority for all facilities. The stationary source standards governing HAP emissions in manufacturing are known as the National Emission Standards for Hazardous Air Pollutants (NESHAPs). Today we will discuss the changes made to Subpart IIII for the Surface Coating of automobiles and light-duty trucks, particularly how to demonstrate compliance using reference tables.

Who is Subject to Part 63 Subpart IIII?

Part 63 Subpart IIII covers automobile and light-duty truck surface coating facilities. It includes any facilities that apply the coating to new motor vehicle bodies, body parts for new motor vehicles, and other parts to be used in motor vehicles or aftermarket repair and replacement. This subpart also requires that your facility be a major source, located at a major source or part of major source emissions of HAPs.

A major source of HAP emissions is defined as a facility that emits or has the potential to emit any single HAP at a rate of 9.07 megagrams (Mg) (10 tons) or more per year or a combination of HAPs at 22.68Mg or more per year.

You are not subject to this rule if:

- Your coating operation is located at a plastic moulding facility

- The top coated body parts were fabricated at your facility or at an external plastic to composites moulding facility owned by your company, and the vehicles are not assembled at the same facility.

- You do not topcoat all the body parts for any single new automobile or new light-duty truck at your facility.

Click here to read the full rule and exemptions.

NESHAP Organic HAP List Changes in 40 CFR: Introducing Table 5

Up to 2020, demonstrating compliance for this subsection meant using the OSHA carcinogens list to classify your chemicals. OSHA-defined carcinogens are industrial agents that can cause cancer; they are often listed as such in their Safety Data Sheets (SDS). Safety data sheets always contain carcinogenicity information to help manufacturers take the correct precautions when using them in their facilities.

The rule was updated in July 2020 to feature Table 5, which contains the list of HAPs that must be included in total organic HAPs content calculation if present at 0.1% or more by mass. All other organic HAPs (not listed in Table 5) should be listed if present at 1% or more by mass. Instead of checking for chemicals on the OSHA carcinogens list, you should now refer to 40 CFR Part 63 Subpart IIII Table 5.

Part 63 Subpart IIII Table 5: List of HAPs That Must Be Counted Toward Total Organic HAP Content if Present at 0.1 Percent or More by Mass.

| Chemical name | CAS No. | Chemical name | CAS No. | |

| 1,1,2,2-Tetrachloroethane | 79-34-5 | Dichloroethyl ether | 111-44-4 | |

| 1,1,2-Trichloroethane | 79-00-5 | Dichlorvos | 62-73-7 | |

| 1,1-Dimethylhydrazine | 57-14-7 | Epichlorohydrin | 106-89-8 | |

| 1,2-Dibromo-3-chloropropane | 96-12-8 | Ethyl acrylate | 140-88-5 | |

| 1,2-Diphenylhydrazine | 122-66-7 | Ethylene dibromide | 106-93-4 | |

| 1,3-Butadiene | 106-99-0 | Ethylene dichloride | 107-06-2 | |

| 1,3-Dichloropropene | 542-75-6 | Ethylene oxide | 75-21-8 | |

| 1,4-Dioxane | 123-91-1 | Ethylene thiourea | 96-45-7 | |

| 2,4,6-Trichlorophenol | 88-06-2 | Ethylidene dichloride (1,1-Dichloroethane) | 75-34-3 | |

| 2,4/2,6-Dinitrotoluene (mixture) | 25321-14-6 | Formaldehyde | 50-00-0 | |

| 2,4-Dinitrotoluene | 121-14-2 | Heptachlor | 76-44-8 | |

| 2,4-Toluene diamine | 95-80-7 | Hexachlorobenzene | 118-74-1 | |

| 2-Nitropropane | 79-46-9 | Hexachlorobutadiene | 87-68-3 | |

| 3,3′-Dichlorobenzidine | 91-94-1 | Hexachloroethane | 67-72-1 | |

| 3,3′-Dimethoxybenzidine | 119-90-4 | Hydrazine | 302-01-2 | |

| 3,3′-Dimethylbenzidine | 119-93-7 | Isophorone | 78-59-1 | |

| 4,4′-Methylene bis(2-chloroaniline) | 101-14-4 | Lindane (hexachlorocyclohexane, all isomers) | 58-89-9 | |

| Acetaldehyde | 75-07-0 | m-Cresol | 108-39-4 | |

| Acrylamide | 79-06-1 | Methylene chloride | 75-09-2 | |

| Acrylonitrile | 107-13-1 | Naphthalene | 91-20-3 | |

| Allyl chloride | 107-05-1 | Nitrobenzene | 98-95-3 | |

| alpha-Hexachlorocyclohexane (a-HCH) | 319-84-6 | Nitrosodimethylamine | 62-75-9 | |

| Aniline | 62-53-3 | o-Cresol | 95-48-7 | |

| Benzene | 71-43-2 | o-Toluidine | 95-53-4 | |

| Benzidine | 92-87-5 | Parathion | 56-38-2 | |

| Benzotrichloride | 98-07-7 | p-Cresol | 106-44-5 | |

| Benzyl chloride | 100-44-7 | p-Dichlorobenzene | 106-46-7 | |

| beta-Hexachlorocyclohexane (b-HCH) | 319-85-7 | Pentachloronitrobenzene | 82-68-8 | |

| Bis(2-ethylhexyl)phthalate | 117-81-7 | Pentachlorophenol | 87-86-5 | |

| Bis(chloromethyl)ether | 542-88-1 | Propoxur | 114-26-1 | |

| Bromoform | 75-25-2 | Propylene dichloride | 78-87-5 | |

| Captan | 133-06-2 | Propylene oxide | 75-56-9 | |

| Carbon tetrachloride | 56-23-5 | Quinoline | 91-22-5 | |

| Chlordane | 57-74-9 | Tetrachloroethene | 127-18-4 | |

| Chlorobenzilate | 510-15-6 | Toxaphene | 8001-35-2 | |

| Chloroform | 67-66-3 | Trichloroethylene | 79-01-6 | |

| Chloroprene | 126-99-8 | Trifluralin | 1582-09-8 | |

| Cresols (mixed) | 1319-77-3 | Vinyl bromide | 593-60-2 | |

| DDE | 601649 | Vinyl chloride | 75-01-4 | |

| Vinylidene chloride | 75-35-4 |

Demonstrating Compliance with the Emissions Limitations

For 40 CFR Part 63 Subpart IIII, you are required to show compliance with operating limits, work practice requirements, and emission limits. For the latter, you must constantly monitor all your equipment and minimize air pollution while maintaining a log that outlines your operation and maintenance systems. Remember also to add control devices and continuous parameter monitoring systems (CPMS) in the specified compliance period.

To demonstrate compliance, you need to determine the mass average organic HAP content, and the amount of each material used, for each regulated material group with a defined emission limit. In the case that every individual material meets the emissions limit, document each of their names and organic HAP content. ERA's software automates these calculations for all Table 5 chemicals and blends, as well as organic HAPs that are not in Table 5, if present at more than 1% by weight.

Mass fraction of organic HAP is equal to the ratio of organic HAP to the total mass of the material in which it is contained.

If you are not using the EPA test methods and calculations, you can also rely on the information provided by your supplier for HAP emission determinations. Evaluate your supplier-provided SDS or EDS to check if your paints and coatings contain any chemicals listed in Table 5 at 0.1% (or more) by mass, or other compounds at 1.0% (or more) by mass. For example, if toluene, a chemical that is not listed in Table 5, is present at 0.5% by mass, it should not be included.

The average organic HAP content for each compliance period should be less than or equal to the emission limits. You must then issue a statement to the EPA that the coating operations complied with emission limitations according to the Notification of Compliance Status Requirements (40 CFR 63.3110).

Recordkeeping and Compliance Reporting are Essential

The EPA states that you should keep compliance records in a form that regulators can easily review. This includes electronic spreadsheets or a database. Since they must be submitted electronically using EPA’s CEDRI, maintaining them electronically makes them accessible in case of an on-site compliance evaluation.

For NESHAP, you must submit semiannual compliance reports (January 1st to June 30th and July 1st to December 31st) for all your regulated sources. If you have a Title V operating permit, include any deviations from your disclosed limits.

Note: This does not replace the need to monitor your Title V permit requirements and report any deviations to the EPA. You must include the variations in Title V and your semiannual NESHAP compliance reports.

A Brief Description of the MCL

ERA's Master Chemical and Regulatory list (MCL) is home to more than 200,000 chemical regulations frequently updated by ERA scientists. It is the backbone of ERA’s software, as information on these chemicals is used for SDS authoring, product approval, and environmental reporting. ERA consistently adds all updated regulations; the NESHAPs that have been updated for September 2022 are outlined below.

Table Showing the New Additions to ERA’s MCL

|

Regulation Name |

Regulation Description |

|

EPA_HAP_Organic_Part63_Subpart_IIII_Table_V |

Organic Hazardous Air Pollutant, Part 63, Subpart IIII, Table V |

|

EPA_HAP_Organic_Part63_Subpart_IIII_Table_V_Deminimis |

Organic Hazardous Air Pollutant, Part 63, Subpart IIII, Table V, De minimis |

Demonstrating Compliance Using NESHAP Reporting Software

ERA's NESHAP and MACT reporting software carries out all the calculations required for NESHAP reporting, including determining mass average organic HAP content for all your chemical groups using material density and volume of the material used. With access to usage records, the system makes your reporting seamless and allows you to check your data for deviations from your Title V permit. It also has a platform that documents the HAP content for many chemicals, which reduces the time spent investigating whether a product contains HAPs or not. To learn more about this compliance solution, schedule a consultation call with a project analyst below.

Tags:

Environmental Management

October 17, 2022

Comments