The Globally Harmonized System (GHS) for Safety Data Sheets (SDSs) has gained huge mindshare amongst many facility, safety & environmental managers in the last 12 months.

The Globally Harmonized System (GHS) for Safety Data Sheets (SDSs) has gained huge mindshare amongst many facility, safety & environmental managers in the last 12 months.

Since the North American Occupational Health & Safety regulators have committed to adopting the Globally Harmonized System (GHS) for chemical hazard communications by 2015, the clock has been ticking for companies to get their affairs in order.

However, as of December 1, 2013 the GHS roll-out has already begun with a strict regulatory deadline that all manufacturers that use or produce MSDSs must have complied with by now.

So, has your business missed this first GHS deadline or have you ALL of your affairs in order?

If your business uses or authors MSDSs, you are required to provide comprehensive training to your staff about how to read and understand the new GHS Safety Data Sheet (GHS SDS) format. By the time the full GHS implementation rolls out, your staff should already be 100% confident in how to properly read a GHS SDS in order to mitigate health risks and on-site incidents.

If your business missed the deadline, you are at risk and could be held accountable should OSHA decide to check in and do an audit on you. The time is now to develop training materials and share them with your staff.

This article will provide you with a basic rundown of some of the major differences between the old MSDS and the new GHS SDS, along with a few other items including:

- Training for the new GHS

- New Standardized Classification System

- Hazard Statements

- Signal Words

- Pictograms

- Formatting

Considering that all MSDSs will be replaced with GHS-style Safety Data Sheets in the coming year (and some of your vendors and partners may already be making the switch early) it is vital that you and your employees understand what changes the GHS transition will bring.

What is the GHS and Why is North America Adopting it?

The Globally Harmonized System has been developed by a joint effort of United Nations members in order to standardize the way that chemical hazards are communicated across international borders. Groups from UN countries have worked to share their own hazardous communication (HazCom) standards and create a combined final system that gives the best possible information without creating too large an implementation burden on SDS authors.

Many countries have already implemented the GHS for their HazCom standards and have been using it for years. Others, like the United States, have been part of the GHS development and are now starting the implementation phase.

Since the GHS transition represents a significant change to North American standards, the transition is being done slowly over a 3 year process. Late 2013 and 2014 is focused on training and preparation for the GHS standards, 2015 will be about proper implementation and full-scale use, and 2016 will be used to make any updates or modifications that are found to be necessary after a year of using the GHS standards.

You can view the United States Department of Labor OSHA full schedule of effective dates online here.

There are many projected benefits to adopting the UN’s GHS standards. OSHA has predicted millions of dollars in savings due to greater capacity for accident prevention. Manufacturers will have access to improved information about the materials and chemicals they use and store on site. Environmental reporting and other compliance reports will be easier to process with clearer information, making them more useful for the reporters, regulators, and the public. Shipping materials to and using materials from other countries will be easier and faster.

Many U.S. businesses have already begun the process of implementing GHS standards for their HazCom needs so that they can be ahead of the competition when the next GHS deadline arrives. In addition, using the GHS provides greater access to international trade and sales opportunities, making early adoption a wise investment.

Ultimately, the GHS will become North America’s new standard, so the sooner you can master it and incorporate it into your operations the better off you’ll be.

Training for the new GHS Standards

The changes brought in by the switch to GHS SDSs are significant, but anyone familiar with managing materials or chemicals will be familiar with the logic employed by the GHS. The new GHS SDS sets out to standardize material classification and communications used across participating UN countries – and that includes using or improving on existing elements used by U.S. manufacturers.

OSHA has provided guidelines for the minimum requirements of your training program. Here’s a quick breakdown, though be sure to take the time and read the official OSHA document as well:

- The type of information the employee would expect to see on the new labels including:

- Product identifiers – chemical name, code, batch number, etc.

- Signal word – either “danger” or “warning”

- Pictograms – symbols used to provide at a glance material hazard info

- Hazard statements – statements about a material’s hazards based on GHS classification categories

- Precautionary statements – a phrase describing how to prevent or minimize adverse effects related to the material’s use

- Contact information – about the chemical manufacturer, importer, or distributer

- How an employee might need to use the new GHS SDSs or labels in their workplace.

- A general understanding of how the elements of the GHS label work together on a label. Also, where to find the types of information that employee might need to find.

- How GHS labels and GHS SDS are related (i.e. precautionary statements would be the same on both for the same material).

All of the above training requirements are nothing new for EH&S professionals and other employees who regularly process material information, so meeting the training requirements shouldn’t be too heavy a burden – so if you missed the December 2013 prioritize the training as soon as possible.

The following sections describe some of the most important and most sweeping changes from the MSDS format to the GHS standards. Keep in mind the training your EH&S or Human Resources teams provide should point out these differences, but also give staff a full understanding of how the GHS functions.

This leads us to the new standardized classification system…

New Standardized Classification System

The standardization of the GHS is largely driven by the new classification system at work within the GHS.

Chemicals are classified using data from tests, literature, and practical experience of GHS developers. From these GHS classifications a chemical is assigned appropriate hazard statements. These different hazards are then used to assign signal words, pictograms, and precautionary statements.

If you are required to author an SDS or label, it is crucial that you assign the correct GHS classifications to your products. OSHA recommends referring to the GHS “Purple Book”, the official UN handbook for any GHS implementation along these lines.

Because the classification system used by the GHS is comprehensive, many manufacturers of chemicals or chemical blends are now turning to GHS experts and GHS software specialists to ease the transition.

Hazard Statements

The GHS standards for labels and SDSs uses a specific set of hazard statements to describe the hazards associated with a chemical – for example: “Heating may cause a fire.” A label or SDS can contain as many hazard statements as necessary to communicate the dangers of the product. OSHA allows authors to “combine where appropriate” to reduce redundancy if a product contains chemicals which repeat the same hazard statement.

The hazard statements associated with a chemical can fall into three categories: physical hazards, health hazards, and environmental hazards. For a full description of each category and subcategory refer to OSHA’s online GHS guidelines or the GHS “Purple Book”.

- Physical hazards are generally those hazards that can cause physical harm to anyone using the material and the equipment/objects associated with the material. For example, physical hazards include explosives, flammable gases, self-reactive substances, oxidizing liquids, and corrosives.

- Health hazards are those risks associated with using a chemical that have an impact on human health through exposure. Some examples include acute toxicity, skin corrosion, carcinogenicity, aspiration toxicity, organ system toxicity (either through repeat or single exposure).

- Environmental hazards describe the negative impacts of a material when released into the water, air, or land, including the impact on exposed wildlife. This category includes acute aquatic toxicity and rapid bioaccumulation potential.

Signal Words

The GHS uses only two signal words “Danger” and “Warning” to indicate the level of danger that a particular chemical presents. Danger is used to indicate a higher level of risk, while Warning is reserved for less severe hazards. These signal words correspond to the new GHS hazard statements.

A GHS label will only ever have one signal word on it, corresponding to the highest possible hazard level related to the product. For example, if a material presents several “warning” hazards and one “danger” hazard, the GHS label will only display the signal word Danger.

New Precautionary Statements

The GHS uses standardized precautionary statements to describe recommended actions to prevent or reduce the risks associated with using a chemical. Many of the precautionary statements of the GHS will be familiar to North American workers, though the wording of some phrases may be slightly different. Be sure to use the standardized precautionary statements on all GHS labels and SDSs.

The GHS contains dozens of new official precautionary statements, which can be found in the GHS “Purple Book”. Each one also has an assigned code, though the statement is what must appear on your GHS labels and SDSs.

It is important to note that certain GHS precautionary statements are customizable. For example, precautionary statement P220 “Keep/Store away from clothing/…/combustible materials” requires the author to select whether the label should stay keep away from clothing, keep away from combustible materials, both, or to fill in the “…” with the most appropriate word. P264 “Wash … thoroughly after handling” could be filled in with any body part or tool that would be exposed to the material.

Pictograms

The pictograms used by the GHS are perhaps the most familiar to North American users, as they are commonly known within the United States and Canada. For example, skull and crossbones are the current standard for communicating a toxic chemical that should not be swallowed.

For new GHS users, training should include information about which pictograms refer to which hazard categories and hazard statements. The skull and crossbones pictogram could refer to a chemical that is fatal if swallowed, toxic if swallowed, or that is acutely toxic. It’s important that anyone in charge of authoring SDSs or labels know which pictogram(s) should be applied.

GHS pictograms are standardized to display a black symbol on a white background framed by a red shape on a point (i.e. a diamond rather than a square). OSHA has ruled that materials not for export can be framed within a black frame rather than a red frame.

The GHS also uses a standardized set of pictograms for shipping and transportation labels.

GHS Formatting

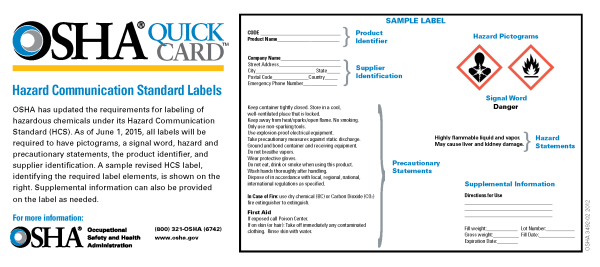

Your training should also demonstrate to employees what the new GHS labels they’ll be encountering will look like. OSHA provides a useful template image in its online guide.

The sections referenced in the above image (taken from OSHA’s website) are found in the GHS “Purple Book”.

Next Steps

If you have yet to complete a GHS training program at your workplace, your first priority should be to review OSHA’s GHS documentation and create a GHS training program.

Once that is complete, or if you did not miss the December 2013 training deadline, it’s time to begin the first steps of full GHS implementation. Ask yourself:

- Do you have a system in place for the GHS transition?

- What is the scope of your GHS responsibilities? SDS authoring? Labelling? Training?

- Who or what will be responsible for authoring GHS compliant SDSs and Labels?

- How will you archive your old MSDSs and how will you manage EH&S data during the transition from MSDS to SDS?

There are many options available to you, depending on your needs and responsibilities. Manufacturers large and small are already beginning to transition to the GHS, using SDS software to more easily classify and author SDSs & labels for their products.

Finding the right solution for your business will be essential in the coming years of GHS implementation.

If you'd like to learn more about using the GHS transition to update and improve your SDS management system, download our detailed guide that covers the topic in Plain English.

Ask an ERA Expert:

Are you transitioning to the GHS in your business? Do you have any questions or concerns about the topic covered in this article? Want more insight? Now is your chance to ask one of ERA’s Environmental Specialists. Please leave your question or comment below and we’ll make sure one of our expert scientists responds.

This Blog was Co-Authored By:

February 14, 2014

Comments