Many countries around the world have set ambitious targets for the transition to electric vehicles (EVs), with some targeting 100 percent of new consumer vehicles being electric. The rapid increase in demand is putting stress on already strained supply chains for critical minerals used in EV battery production. One estimate predicts lithium and nickel demand to increase by 575 and 1,237 percent by 2030, respectively. With limited deposits available and concerns over environmental sustainability and supply chain ethics abound, EV battery recycling will play an increasingly critical role in meeting that demand.

Electric Vehicle Battery Recycling Basics

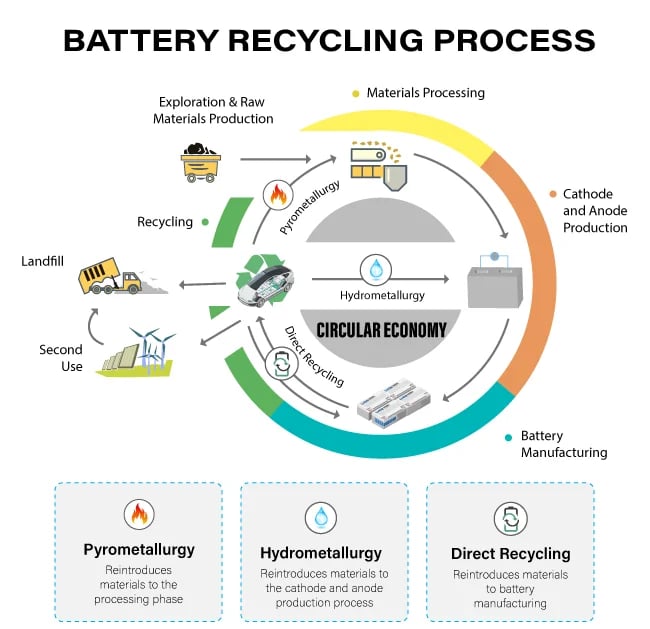

EV batteries contain various critical minerals with limited natural reserves, leading to high prices and long-term supply concerns. Battery recycling can recover many of these materials, allowing for reuse in new batteries or other downstream applications. Several key methods effectively recycle battery materials and integrate them into the overall battery manufacturing process.

Direct recycling disassembles batteries and physically separates the anode, cathode, and other materials. They may require further treatment through methods such as calcination. Cathode material can often be directly recovered and utilized in new batteries, integrating into the final manufacturing and assembly steps.

Pyrometallurgy applies heat to the metal oxides to extract them as other metal compounds, similar to many processes used to refine natural ores. Smelting creates an alloy of the metals inside, which provides raw material for the refining step of battery production.

Hydrometallurgy is another technology for battery recycling that takes a chemical approach. Acid leaching can extract and separate a variety of metals from battery materials. Carefully controlled parameters dissolve certain compounds, and subsequent changes to pH and other factors precipitate the targeted metals to provide material for cathode production.

Each of these technologies provides effective solutions for recovering certain materials. The EV battery recycling industry relies on all of them to achieve the highest possible efficiency.

Why Electric Vehicle Battery Recycling Matters Today

EV battery recycling has positive impacts on both the environment and society. As the demand for batteries continues to increase, expanding recycling efforts will help reduce reliance on new mineral extraction.

For traditional internal combustion engine vehicles, the majority of lifecycle GHG emissions are from burning fuel, whether gasoline, diesel, or otherwise. A smaller portion of emissions come from the manufacturing process, such as those from steel production.

This trend reverses for electric vehicles. The electricity generation needed to power EVs still produces some GHG emissions, even when grids rely on renewable sources. However, those emissions are much lower. This means that it’s actually the manufacturing process itself that creates the majority of lifecycle emissions for EVs, depending on the major sources for local electric grids.

EVs require just as much steel, plastics, transportation, and overhead as internal combustion vehicles. However, they also incur emissions related to mining and processing critical battery minerals. The battery alone accounts for up to 60 percent of emissions during production. Creating a circular economy with less reliance on new mineral extraction can greatly reduce these emissions.

There are also many social concerns related to EV battery production. Many of the critical minerals used today come from conflict zones, such as in the Democratic Republic of the Congo (DRC), or countries that pose serious concerns over labor ethics and market fairness, such as China. As of 2019, the DRC produced 70 percent of new cobalt mined globally.

The transition to a stronger reliance on recycled materials will help reduce demand for new mineral extraction. In turn, the world will be better situated to confront the ongoing challenges of climate change and supply chain ethics.

Modern Efforts to Advance EV Battery Recycling

Many initiatives are underway to increase battery recycling, coming from the government, industry groups, and battery manufacturers. Various programs focus on incentivizing recycling, penalizing waste, and tackling the practical challenges of battery recycling to make it more accessible across the entire EV lifecycle.

One of the most significant measures in terms of regulation is the US Inflation Reduction Act of 2022 (IRA). This act tackled many different areas related to industry and the environment, including EV battery manufacturing. The IRA imposed measures to move critical supply chains away from countries of concern and promote increased battery recycling in North America.

Battery certificates or passports are another important trend that will guide battery recycling over the coming years. A digital document will carry a wide range of information about vehicle batteries, with easy access via serial numbers or barcodes. That information will include details such as composition, recycled content, country of origin, and even end-of-life instructions for recycling.

In the European Union, regulations have laid out a framework and timeline for battery passport implementation. Similar initiatives are underway in other countries, while some, such as the US, have yet to take specific action. Many independent manufacturers, industry action groups, and research organizations are working on practical methods to implement battery certificates.

Tackling EV Battery Recycling Challenges With the Right Software

Choosing the right software solutions plays an essential role in tackling the practical challenges of battery recycling. ERA’s Traceability Software lets battery manufacturers and other organizations throughout the supply chain maintain transparency and ensure that materials come from ethical, environmentally friendly sources.

Within battery recycling operations, dealing with various hazardous wastes is critical. ERA’s Waste Management Software lets these organizations properly track waste throughout their processes. This supports accurate environmental reporting and health & safety compliance and ensures proper accounting for waste credits used in certain incentive programs.

Today’s Efforts Set the Stage for a More Sustainable Tomorrow

EV production is rapidly increasing and will continue to do so into the future. The world will soon face unprecedented demand for critical minerals and must turn to EV battery recycling on a similar scale to ensure that production is ethical and environmentally sound. While challenges are still ahead, the combination of new technologies and ongoing efforts by governments, industry, and consumers continue to push EV battery recycling forward.

Contributing Scientists of This Article:

March 1, 2024

Comments