Air Compliance is an essential part of facility management. Your facility may already have elaborate systems in place to manage your air emissions, but most facilities do not consider emissions that come from waste at all when it comes to their air reporting. Industrial waste management practices can help you improve your compliance by factoring in emissions from waste and waste management activities. Does your current Clean Air Act (CAA) emission reporting process consider your waste? This article will show you why it should.

Air Compliance is an essential part of facility management. Your facility may already have elaborate systems in place to manage your air emissions, but most facilities do not consider emissions that come from waste at all when it comes to their air reporting. Industrial waste management practices can help you improve your compliance by factoring in emissions from waste and waste management activities. Does your current Clean Air Act (CAA) emission reporting process consider your waste? This article will show you why it should.

The ‘Airborne Emission Regulations for Hazardous Waste Management Units’ guidance document from the EPA can be used to help you understand and formulate your factory pollution solutions because there is no specific regulation that addresses industrial waste generation and disposal in individual facilities. These regulations include:

- Hazardous Waste Management Unit Airborne Emission Regulations that cover where the waste is located on the facility including tanks and impoundments, the emissions in these areas should be reduced by 95%. It also covers the monitoring of leaks and valves to highlight repair requirements and organic emissions from pollution caused by the chemical industry.

- Municipal Soil Landfill Regulations cover degradable and nondegradable pollutants. This includes decomposition gases, dust during transport and treatment emissions. This regulation requires a gas collection system with 98% emission reduction in the landfill facility.

- Offsite Waste and Recovery Operations NESHAP covers waste that emits Hazardous air pollutants (HAPs). This includes waste oil or solvents and management of waste storage devices such as tanks to reduce leaks and HAP emissions.

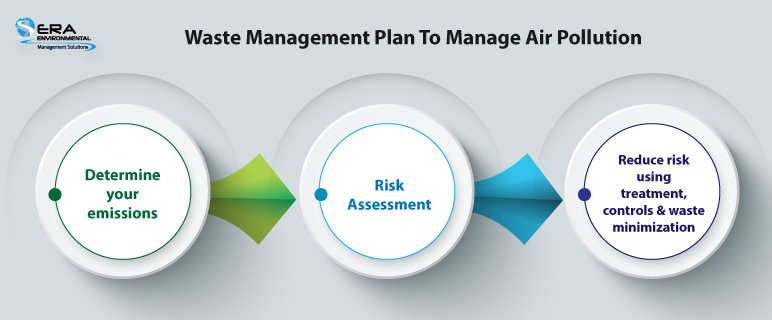

These regulations are not directly enforced by EPA for facilities that don’t specialize in hazardous waste management. Regardless, they are a good baseline for improving your environmental performance by considering air pollution from waste which is usually not accounted for in CAA emission reporting. Making the shift to include reporting air pollution from waste will increase your facility’s compliance standing and data accuracy. Using these regulations that are meant for waste management facilities will effectively improve your air reporting. Below is a flow chart showing you how you can start your waste management plan to manage air pollution from waste:

![]()

Determining your emissions is an important step in waste management. This includes where your waste is stored, how it is moved, and other emission possibilities. Depending on your waste disposal practices, you can determine your emissions by either requesting a report from your treatment, storage, and disposal facility (TSDF) or by calculating the chemical content as a ratio of materials and chemicals used that contribute to waste. The amount of waste generated affects how long the waste is on-site: Very Small Quantity Generators (VSQG) and Small Quantity Generators (SQG) tend to have waste on-site for longer, which means they have to pay more attention to where the waste is stored on-site even though it may not have significant emissions. Large Quantity Generators (LQG) transport their waste to TSFDs more frequently. They need to pay more attention to how they transport their waste and how air emissions can arise from these practices. Knowing which category your facility falls into will help in choosing the right waste management practices.

Emission Control Recommendations and Improvement Tips for Industrial Waste Management

Controlling Particulate Matter

Non-hazardous Air pollutants that have the potential to become airborne, Particulate Matter (PM) can originate from the combustion of fuels, soil, and dust generation from both mobile and stationary sources of air pollution. The first control of PM in your factory pollution solutions is vehicular. This involves controlling the waste generated during transportation. Pollution from PM can come from the load that is carried in the vehicle, the location of the vehicle, or from the type of road within your facility.

If your waste produces a high amount of PM, cover it with a tarp or put in double bags; this will reduce the amount that is released into the atmosphere. If there are vehicles that are transporting PM, make sure they stay within the facility for that primary function to limit external air pollution.

Waste placement and handling is also a source of air pollution by PM depending on the type of waste that is produced. If the waste has a high moisture content, it is less likely to become airborne. The EPA recommends wetting dry waste to reduce PM. Ensure that you don’t add excessive moisture because that could negatively impact the ground and surface water quality. We recommend that you experiment until you find the right amount of water application that does not increase the risk of alternate land or water pollution.

Applying chemical dust suppressants to the waste is also a useful method of controlling PM. These are detergent-like chemicals that make dust particles stick together more efficiently which increases the surface area of the particles. This makes the particles less likely to become airborne. This method is a better alternative to water because it requires less frequent application. You need to ensure that you are using the right chemical for the type of waste that you produce. The EPA has a list of chemical suppressants that you may find useful within their industrial waste management guide.

VOC Emission Control Techniques

Volatile Organic Compounds (VOCs) emitted from waste can contribute to your facility's total emissions. Five practices can be incorporated into industrial waste management to manage the emission of VOCs:

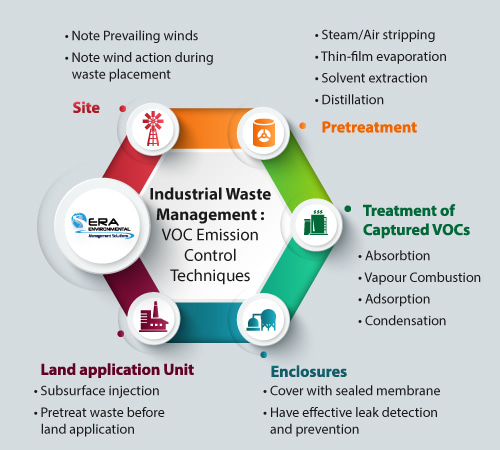

The first thing to consider is the location of the waste site. The site must be in a position that minimizes airborne emissions. You need to take note of the direction of prevailing winds and evaluate if the wind carries to nearby areas. This way, you can ensure that the site is not upwind of these areas. Wind action should also be considered during waste placement because that is when vapors are most likely to be carried away by the wind. Another storage consideration is how often the space must be monitored. For example, petrochemical companies have most of their waste stored in tanks which require monitoring and venting. You should select a waste location that will not be affected by wind and monitor the waste accordingly.

Another method of managing VOCs is through waste pre-treatment. This ensures that the volatiles are removed as close to waste generation as possible. That way, there are fewer stages in the process that need to be addressed. Examples of treatment are listed in the diagram above. Some treatment methods require separate permits; therefore, you should take note of this before selection. Solvent distillation is an exception to the permit rule and can also help with re-collecting the chemicals for other processes in your facility.

The enclosure of waste locations is another method of managing air emissions from waste that is used by various waste management facilities. This involves covering the waste with flexible membranes or storing it within an enclosed unit where the VOCs can not be released into the atmosphere. An efficient cover must:

- Be efficient in preventing leaks and have a functional leak detection system such as optical leak imaging using gas detection cameras.

- Made from a good material with adequate thickness for gas containment.

- Must have a seal at the edge to limit the escape of gases.

- Gases formed within the enclosure must be sent to a control device such as a carbon absorber to reduce the amount that is being released into the atmosphere.

- Have safety procedures for workers that will be accessing it.

- Rainwater must be removed from the unit.

Other methods of enclosing waste units include installing wind fences and wind barriers this can reduce the amount of gasses being carried by the wind and can protect the waste from moisture loss due to wind. Wind can carry both gases and PM.

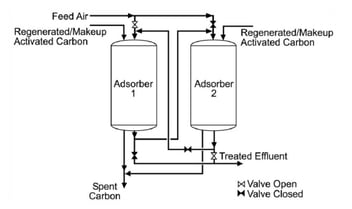

The captured VOCs must also be treated using the methods in the diagram above because they still pose risks to the environment if they are emitted. Adsorption is when particles are trapped on the surface of a filtration matrix. This can be done by passing the VOCs through a carbon filter or Biofilter that traps the VOCs and release Clean air.

Image showing two types of adsorption, Carbon filter.

Condensation is also an effective treatment method. This is when the VOCs are cooled and collected in liquid form. Absorption is when the VOCs are dissolved in either water or mineral oils and then disposed of. This method is inefficient because the disposal of the liquid is difficult and may alternately cause pollution.

Waste generated VOCs can also be treated by combustion with an efficiency of 98%. A concentrator is used to compact the gasses before being combusted using flares, incinerators, and catalytic oxidizers. Most companies use regenerative thermal oxidizers that have a 95% destruction efficiency. When you incorporate vapor combustion, you must ensure that the process design is well managed.

The above-mentioned methods ensure that the land application units of waste emit minimal amounts of VOCs but here are some extra considerations for your land application units from the EPA:

- Spraying waste increases the contact of waste and air which may promote VOC emissions so if you know that your waste contains VOCs avoid spraying it and this will limit your VOC emissions.

- Injecting your waste at least 6 inches into the soil (subsurface injection) is a good practice to ensure that it is not in contact with the atmosphere.

- Always pre-treat the waste before placing it in the land application unit, this will remove the VOCs and avoid seeping into the land and groundwater.

Tracking Air Emissions Generated by Waste

Tracking Air emissions produced by your waste is important both before and after implementing the industrial waste management recommendations in this article. You will need to know how these practices have affected the number of total emissions produced by your facility. Using software to track your waste will ensure that you are able to quantify your air emissions and that you improve your annual air reporting. ERA’s emission tracking tool can help you manage your emissions accurately and comprehensively.

This Blog was Co-Authored By:

Tags:

Waste Management

January 7, 2021

Comments