Section 608 of the Environmental Protection Agency’s (EPA) Clean Air Act (CAA) deals with rules and regulations about refrigerants and how technicians, owners, operators, and reclaimers use, manage, store, or dispose of them as well as establishes rules on record-keeping. It also sets regulations on recycling and reclaiming. While the EPA's Section 608 covers policies affecting technicians, it has also impacted leak and inspection rates. This article discusses the most recent change; the complete ban of refrigerants R-22 (HCFC-22) and HCFC-142b on January 1, 2020 as well as how changes to leak and inspection rates in 2019 demonstrate that finding a sustainable solution for refrigerant leakages is not only cost-effective, but key to staying compliant with Section 608 regulations.

Section 608 of the Environmental Protection Agency’s (EPA) Clean Air Act (CAA) deals with rules and regulations about refrigerants and how technicians, owners, operators, and reclaimers use, manage, store, or dispose of them as well as establishes rules on record-keeping. It also sets regulations on recycling and reclaiming. While the EPA's Section 608 covers policies affecting technicians, it has also impacted leak and inspection rates. This article discusses the most recent change; the complete ban of refrigerants R-22 (HCFC-22) and HCFC-142b on January 1, 2020 as well as how changes to leak and inspection rates in 2019 demonstrate that finding a sustainable solution for refrigerant leakages is not only cost-effective, but key to staying compliant with Section 608 regulations.

Phasing Out HCFCs And HFCs

Initiated in 2010, the EPA started a 10-year plan on how to completely phase-out refrigerants that contain hydrochlorofluorocarbons (HCFCs) and chlorofluorocarbons (CFCs) which are ozone-depleting substances (ODS) contributing to climate change. In 2010, the import and production of HCFC-22, (commonly referred to as R-22 refrigerant, popularly known as Freon) and HCFC-142b, were banned. However, servicing equipment was still acceptable. The EPA’s long-term goal is to completely ban the production and import of all HCFCs by 2030, as established by the Montreal Protocol in 1987.

January 1, 2020: Banning Of Refrigerant R-22

As of January 1, 2020, the 3rd phasing out period will be complete. This means that it is still legal to use refrigerants R-22 and HCFC-142b, however they will only be available through recycled or reclaimed forms. Technicians and reclaimers alike will need to follow strict rules laid out by the EPA regarding servicing equipment and be Section 608-certified. Because this transition has been in the works for 10 years, it is no longer a shock to industries using refrigerants containing HCFCs and CFCs.

What Is The Best Replacement for R-22?

According to the EPA, the most common R-22 replacement is R-410A, which is a non-ozone depleting hydrofluorocarbon (HFC) refrigerant. To facilitate the usage of more health and environmentally friendly substances, the EPA established the Significant New Alternatives Policy program (SNAP) which evaluates the risks of substances and provides information on them, so that industries can make informed choices. What’s great about the list is that it’s always evolving as the EPA gains knowledge about various substances and makes regulatory decisions. SNAP listings are categorized by end-use and classified by acceptability criteria , based on how the substitute fares compared to other substitutes for a specific end-use. In terms of refrigerants, you can search for substitutes based on your refrigeration and air-conditioning end-uses such as chillers, cold storage warehouses, household refrigerators and freezers and so on. It’s important to note that the EPA uses the scientific term HCFC-22 to refer to refrigerant R-22 in its listings.

Changes To Leak Rates In 2019

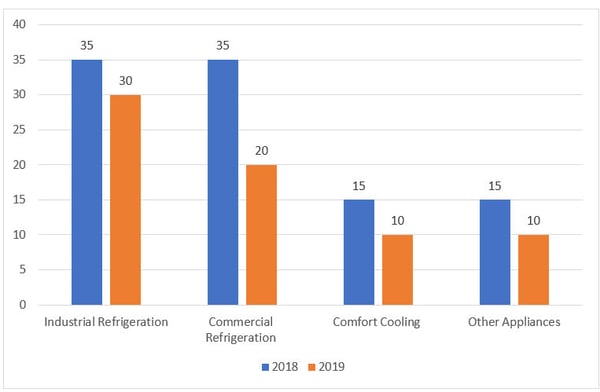

While industries relying heavily on refrigerant R-22 have had time to adjust to the ban, what was probably the biggest change to adapt to, happened in 2019 with stricter rules on leak rate thresholds and inspection rates. For instance, leak rate thresholds decreased significantly:

Leak Rate Thresholds (%)

(Effective January 1, 2019)

These leak rates apply for a 12-month period. Commercial refrigeration is the sector that touches the most businesses and it also represents the biggest change in threshold. It’s also important to know that leak rates are to be calculated every time a refrigerant is added to an appliance.

If you are spending a lot of time doing leak rate calculations by hand or in Excel, you might want to consider other options. For example, investing in a system that does this for you would not only free up some of your time, but also assist you in staying compliant with the EPA's Section 608. ERA’s Refrigerant Management System calculates leak rates automatically using the EPA’s leak rate. It also tells you when you need an inspection and it allows you to fill out an inspection form, as required by the EPA— this is crucial as the EPA has strict rules and larges fines around record-keeping.

Changes In Inspection Rates In 2019 By The EPA

What was also significant was the change in inspection rates:

| Type of Refrigeration/Cooling system | Weight/Inspection frequency |

|

For commercial refrigeration and industrial process refrigeration equipment weighing |

500 lbs and over: inspection required every 3 months until the leak rate has shown to not exceeded the threshold for four quarters in a row. |

| 50 to 500 lbs require an inspection once a calendar year until the leak rate has shown to not exceeded the threshold for one year. | |

| For comfort cooling equipment |

50 lbs or less: an inspection is required once every three months until the leak rate has shown to not exceeded 10% for one year. |

If any system hits the 125% leak rate in the calendar year, it is required to report to the EPA, complete with any documentation on the work that was done.

It’s interesting to note that these inspection requirements only pertain to owners and operators who aren’t equipped with an automatic leak detection system (ALD). This points to how beneficial it would be for businesses to convert to systems that monitors and tracks leaks, as it would not only avoid large costs related to loss of refrigerants, inspection and more costly repairs.

Some Advice From Industry Leaders and Experts

Firstly, ensure that your equipment is working properly and have repairs done quickly.

While these regulations are tough, most industry leaders and experts assert that it is well-worth the effort to make sure that your equipment is getting serviced regularly and operating efficiently. It is more costly in the long run to have equipment that is running poorly and leaking. For example, the EPA states that most supermarkets have a refrigerant charge of 4000 lbs and an annual leak rate of 25%, which means roughly 1000 lbs of refrigerant leakage per year.

Secondly, keep track of all work done on your equipment, complete with dates and receipts. You must keep the records for at least 3 years. Fines for EPA non-compliance are extremely hefty, starting at $37,500 per day, which doesn’t include costs associated with repairs or replacements.

Thirdly, seriously consider switching to an automatic leak detention system, as you would not be required to do periodic leak inspections. If you want to go even further, there are refrigerant management systems available which not only track leaks, but also offers a comprehensive list of capabilities in line with the EPA's Section 608 requirements. For example, ERA’s Refrigerant Management System is built to allow owners, operators and technicians to seamlessly keep track of their refrigerant levels, leaks, retrofits and any plans for disposal. It also generates reports so they can track their progress and stay compliant with Section 608.

What Are My Options?

1.Change your refrigerant

Using the SNAP list of refrigerants, convert to a climate-friendly R-22 replacement such as R-410A. According to the EPA, R-410A is manufactured under various trade names such as GENTRON, AZ-20, SUVA, 410A and PURON. It’s always best practice to check with your supplier about retrofitting refrigerant R-22 systems, as a retrofit could be cheaper than purchasing a new system and it would possibly take less time to install. Keep in mind, however that retrofitting will probably void the warranty.

2. Buy new equipment

This would mean incurring more upfront costs, however having a system that is more efficient, could save you more money in the long run, as it will most likely translate into less leak repairs, replacement costs and lower electricity bills.

3. Keep your existing equipment

Older HVAC/R systems manufactured before January 2010 require refrigerant R-22. It is still possible to purchase R-22 from reclaimed or stockpiled sources, however it will be very expensive as the availability will continually decrease, as the ban on import and production will be effective as of January 1, 2020. If your system was built after 2010, it probably uses another refrigerant. If you’re not sure, you can check the nameplate or the user’s manual or speak to a certified technician. In any case, the average lifespan of an air conditioner is 10-15 years, so it may or may not be cheaper to convert to a new system, depending on how well your system is functioning. Besides a cost-benefit analysis, remember that refrigerant R-22 is very destructive to the environment.

4. Fix any leaks immediately

Whether you decide to buy a new system or to only replace parts, ensuring that your system is not leaking is paramount. Besides having a negative impact on the environment, leaks are costly to you and your business. In addition to increasing refrigerant costs, it also means your system isn’t working efficiently.

Further Regulatory Reading

Here's some further EPA reading you may want to reference for government documentation of the Section 608 updates:

https://www.epa.gov/section608/revised-section-608-refrigerant-management-regulations

https://www.epa.gov/sites/production/files/documents/GChill_Retrofit.pdf

This Blog was Co-Authored By:

January 13, 2020

Comments