With rigorous data-gathering and advanced process mapping, ERA's software for National Emission Standards for Hazardous Air Pollutants (NESHAP) and Maximum Achievable Control Technology (MACT) regulations provides total accuracy reporting.

.png?width=550&height=350&name=Tier-II-solution-webpage_desktop%20(1).png)

.webp?width=550&height=350&name=Hero_EMISSION%20(1).webp)

Roll up or drill down emissions data and changes to chemical throughput from any type of source, including data from CMS

Our platform takes care of HAPs, VOCs, VHAPs, GHGs, NOx, SOx, particulate matter, and other criteria pollutants

Emission calculations and material data adhere to the most rigorous standards and are saved in a secure, cloud-hosted vault for peace of mind

Automatically generate air emission reports on a pre-set schedule or on demand (such as in response to accidental releases). Reports come in a digital format that can be uploaded to state reporting e-tools where applicable.

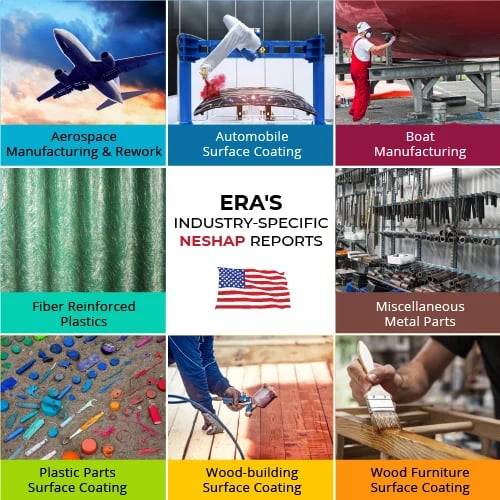

We have industry-specific reports for:

If we don't have your subpart already built into the system, we will design and implement a report for you!

Develop and implement a continuous improvement strategy with real-time monitoring and executive dashboard KPIs across your sites

Send automated email notifications to the appropriate personnel whenever a source approaches and/or exceeds a custom emission threshold

We update our in-house Master Chemical List daily to reflect changes in HAP/MACT regulations, ensuring your reports meet EPA standards

(MACT regulations are listed with their respective industry, where applicable)

Cooling Towers

Equipment Leaks (Control Level 1, 2, Fugitive Emission Sources, and Fugitive Emission Sources of Benzene)

Process Vents, Control Devices, and Flares

Storage Vessels and Transfer Operations (Containers, Tanks- Level 1 & Level 2, Benzene Storage Vessels, and Benzene Transfer Operations)

Wastewater Operations (Benzene Water Operations, Individual Drain Systems, Surface Impoundments)

Beryllium Rocket Motor Firing

Industrial, Commercial, and Institutional Boilers and Process Heaters Major Sources

Industrial, Commercial, and Institutional Boilers Area Sources

Stationary Combustion Turbines

Stationary Reciprocating Internal Combustion Engines (RICE)

ERA's compliance team simplified and compiled boiler emission calculations and relevant MACT data into a short PDF that will kick start your compliance process.

Get an in-depth introduction to MACT standards, the MACT floor, MACT Model Point Value Equations, and other NESHAP regulation need-to-knows.

After working in the automotive sector for over 28 years, ERA has acquired thorough knowledge of the Automotive MACT. We've put it all in this one guide for you.

Understanding your obligations to the Clean Air Act can be complicated. We are here to help.

National Emission Standards for Hazardous Air Pollutants (NESHAPs) were created as an extension of the CAA to monitor the amount of hazardous air pollutants (HAPs) from stationary sources—factories, refineries, boilers, power plants, etc.

EPA auditors regularly conduct inspections on regulated facilities to evaluate compliance and identify and address excess emissions. Inspectors may engage in one or several of the following: