The Colorado Department of Public Health and Environment has recently issued a new General Permit for the Oil & Gas industry, also known as the GP07.

The Colorado Department of Public Health and Environment has recently issued a new General Permit for the Oil & Gas industry, also known as the GP07.

In order to stay in compliance and make your compliance efforts count, it’s important to stay in-the-know about this new general permit, even if you’re currently compliant under an Individual Permit.

However, it is important to note that even if your sources are qualified under a GP07, you are under no obligation to switch from your Individual Permit.

We tasked ERA Environmental’s Regulatory Research team with creating these handy guidelines for understanding the benefits and features of the new GP07 and the types of loadout operations it covers. The new permit was designed to offer two straightforward but much-desired benefits: simplicity and affordability.

Qualified Sources for GP07

The GP07 only covers qualified sources: hydrocarbon loadout sources with actual controlled VOC emissions not exceeding 10 tons per year (tpy) and with total hazardous air pollutant (HAP) emissions not exceeding 20 tpy. In addition, your facility must be able to operate under the conditions of the General Permit. Major sources, and those unable or unwilling to follow the prescribed conditions of the General Permit must use an Individual Permit instead.

It is also essential to note that although an Individual Permit covers both submerged and splash methods of loading cargo, the GP07 only covers submerged loading.

Submerged versus Splash Loading

The General Permit only covers for submerged loading losses while an Individual Permit can cover losses resulting from both submerged and splash loading.

New cargo is either loaded by the splash loading method or submerged loading method. It is important to account for these differences when calculating for reporting requirements. You could easily under or over report if you miscalculate emissions from mixing up the two methods.

If your tanks are filled using the splash loading method, a pipe from above the tank unloads your liquid product by extending partway into the tank. If your tanks are filled using the submerged loading method, product is dispensed into the tank in two ways. A pipe is from above is either lowered until it nearly touches the bottom of the tank, or attached permanently to the bottom of the tank. This allows the tank to be filled while the pipe is submerged beneath the liquid surface level.

Submerged loading -- where the fill pipe dispenses product beneath the liquid surface level -- results in lower turbulence and vapor loss. If you use this method, the GP07 permit may benefit you. If you don’t use it, but it’s possible to execute at your operations, it may be something to consider if the GP07 looks like an attractive option for you.

Loading losses differ with the two methods. As implied by the name, splash loading is "messier" and causes higher levels of vapor loss. The higher up the dispensing pipe from the bottom of the cargo tank, the higher the turbulence during loading.

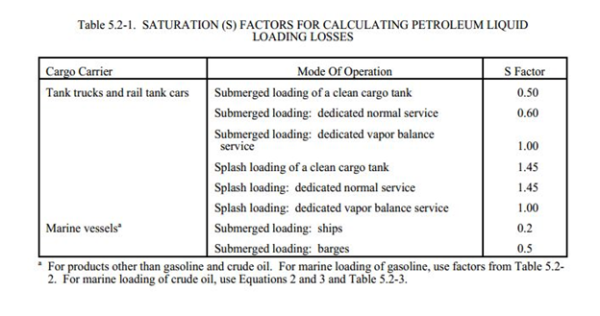

In terms of ensuring your calculations are done accurately, submerged loading uses a lower saturation factor for loading loss, while splash loading uses a higher saturation factor. Specific saturation factors can be found in the Table below.

Further Qualifying Conditions

You qualify for GP07 if you are a source that complies with all terms and conditions in the General Permit:

-

Your facility must not exceed an emissions limitation of VOC 10 tpy, or combined actual controlled emissions of hazardous air pollutants not exceeding 8.0 tpy (individually), or 20.0 tpy (combined).

-

Your facility must not exceed 20% opacity in visible emissions during normal operation.

-

If emissions are routed to a control device, you must follow an Operating and Maintenance Plan.

-

Hydrocarbon Liquid Loadout must be conducted by submerged fill.

-

You must minimize fugitive VOCs by preventing dripping during loading/unloading, close compartment hatches at all times when operations are not active, and inspect loading equipment at least monthly.

-

You must minimize fugitive VOCs to the maximum practical extent.

Read more about conditions and requirements for qualifying under the GP07.

Benefits of the GP07

A More Streamlined Process

The GP07 permit coverage begins sooner than the coverage under an Individual Permit: your facility is permitted under a GP07 immediately upon the Colorado Air Pollution Control Division’s receipt of your application. In contrast, an Individual Permit requires the Division’s full review and approval before you can begin construction and operations.

The GP07 also offers a great deal of flexibility, with built-in Alternate Operating Scenarios (AOS) provisions so that you are able to respond to the most common AOS needs without having to notify the Division of every change in operations you make.

Instead, you will simply have to notify the Division in your annual Air Pollutant Emission Notice (APEN) that you used one of the GP07’s built-in AOS options. This revised APEN notice must include a record of the date, a description of the modification made under the AOS provisions, along with a brief cover letter detailing the change and your reasons, and your APEN filing fee. The APEN must be filed by the April 30th that follows the modification - meaning you may have a full year before a notice is required.

The GP07 comes with the following standard AOS options, and using these options allows you to use the simpler notification process detailed above. Remember that AOS options can be implemented only as a temporary operating scenario with the goal of minimizing emissions:

-

Increase the throughput resulting in facility classification change from true minor to synthetic minor source.

-

Addition or replacement of control equipment by a different type.

-

Relocation of the loading operation within the same quarter-quarter section, township, and range.

One-Time Permitting Fee

The second benefit to using a GP07 is that it does not require payment every time your operations are modified, which could normally cost up to hundreds of thousands of dollars if you’re using an Individual Permit.

This one-time fee also means that you can implement AOS modifications without paying extra fees.

Conclusion: Is GP07 Right for You?

Although the GP07 is more flexible and streamlined, the catch is that its coverage is more general than an Individual Permit. Additionally, equipment descriptions are standard for every loadout operation, whereas an IP provides more flexibility for customized equipment.

Also, the GP07 only permits state default emission factors to calculate emissions while an IP allows the use of site specific emission factors. Abiding by state default emission factors may require you to submit more conservative measures for reporting.

Despite the generalities, the GP07 permit is easier to attain and provides more flexibility for modification. Smaller facilities and those with less complex operations may benefit from the simpler and less costly GP07.

If you feel the permit is right for your hydrocarbon liquid operations, the GP07 may help reduce costs for your environmental compliance.

Ask an ERA Expert:

Do you have any questions or concerns about the topic covered in this article? Want more insight? Now is your chance to ask one of ERA’s Environmental Specialists. Please leave your question or comment below and we’ll make sure one of our expert scientists responds.

Tags:

Compliance

July 10, 2014

Comments